sandbox

CAN-bus sniffing

CANcool

'Berechnungs-Term'

+ // addition

- // subtraction

* // multiplication

/ // division

<< // Bit shift left

>> // Bit shift right

& // AND

| // OR

~ // XOR

d0 1st byte (decimal)

d1 2nd byte (decimal)

d3 3rd byte (decimal)

d4 ...

d5 ...

d6 ...

d7 ...

d0 // unsigned char (8-bit)

(d0 - ((d0 >> 7)*256)) // signed char (8-bit) Two's complement

((d0 << 8) + d1) ^= MSB * 256 + LSB // unsigned short (16-bit)

(((d0 << 8) + d1) - ((d0 >> 7)*65536)) // signed short (16-bit) Two's complement

((d0 << 24) + (d1 << 16) + (d2 << 8) + d3) // unsigned integer (32-bit)

((d0 << 24) + (d1 << 16) + (d2 << 8) + d3)-((d0 >> 7)*4294967296)) // signed integer (32-bit) Two's complement

256 = (1 << 8)

65536 = (1 << 16)

16777216 = (1 << 24)

4294967296 = (1 << 32)

MIA >> Monitor = MIAtor

- parts:

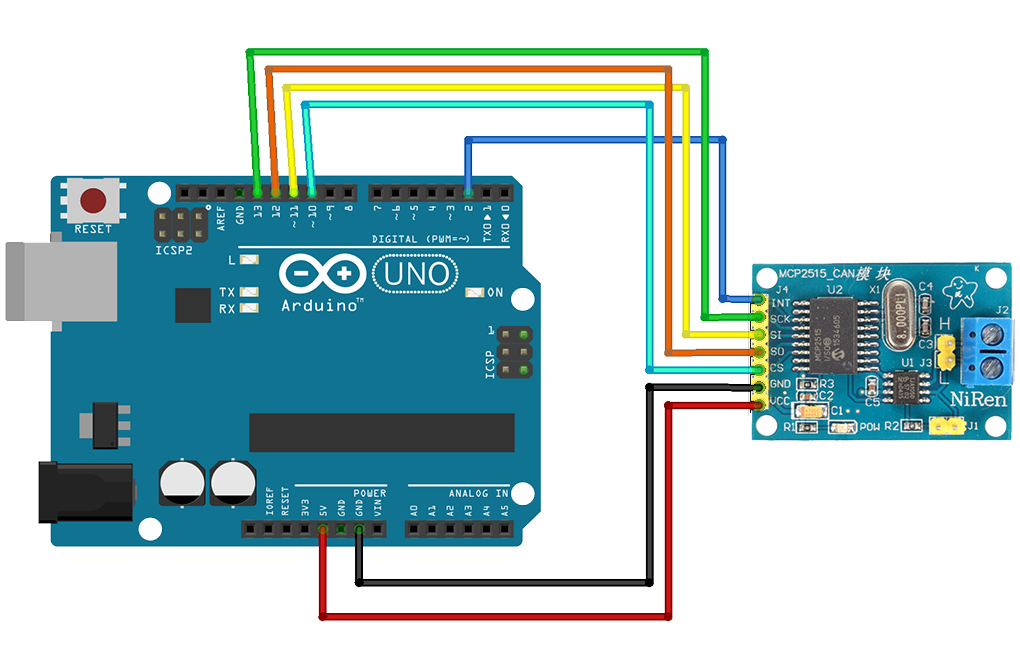

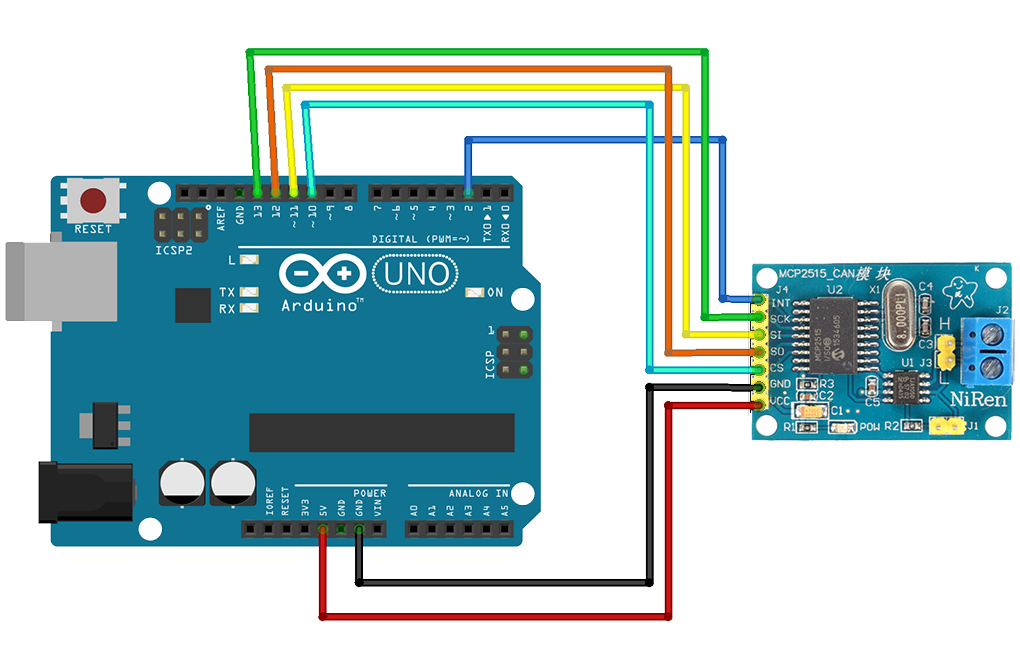

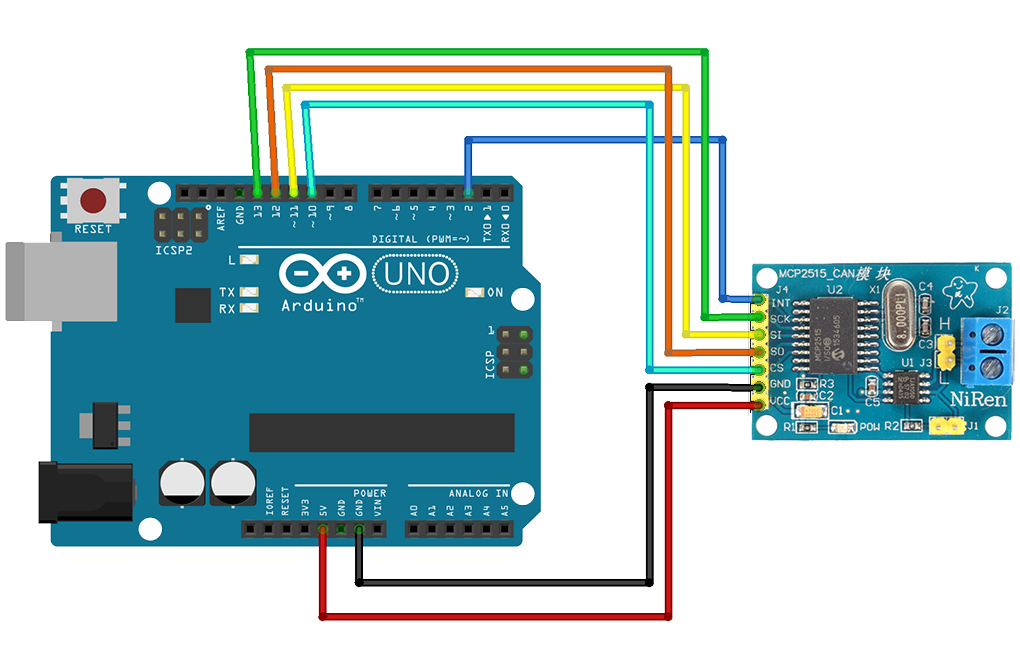

- Arduino UNO R3 (or CH340 clone EUR 6,49)

- MCP2515 / TJA1050 shield

(8MHz EUR 4,79)

(8MHz EUR 4,79)

- OBD-II connector: Pin-6=CAN-high / Pin-14=CAN-low EUR 1,69

- 20x4 LCD display plus I2C EUR 8,77

- libaries:

- code:

// MIA >> Monitor = MIAtor

// all about @ https://bastelbude.grade.de/mediawiki/index.php?title=MIA_electric#MIA_.3E.3E_Monitor_.3D_MIAtor

// based on Voltix's work @ https://miahammia.wordpress.com/2017/10/08/infobox/

// CANbus

#include <mcp_can.h> // https://github.com/coryjfowler/MCP_CAN_lib (clockset to MCP_8MHz at mcp_can.h line 98)

#include <SPI.h>

// LCD

#include <Wire.h>

#include <LiquidCrystal_I2C.h> // https://github.com/marcoschwartz/LiquidCrystal_I2C

LiquidCrystal_I2C lcd(0x3F,20,4); // set the LCD address to 0x3F for a 20 chars and 4 line display

long unsigned int rxId;

unsigned char len = 0;

unsigned char rxBuf[8];

float Volts;

float Amps;

float Celsius;

int SOC;

int SOH;

String Status;

String Emergency;

String Regeneration;

float ChargeCurrent;

float ChargeVoltage;

char myBuf[8];

String LCDline[4];

MCP_CAN CAN0(10); // Set CS to pin 10

void myPrint(){

Serial.println(LCDline[0]);

Serial.println(LCDline[1]);

Serial.println(LCDline[2]);

Serial.println(LCDline[3]);

lcd.setCursor(0,0);

lcd.print(LCDline[0]);

lcd.setCursor(0,1);

lcd.print(LCDline[1]);

lcd.setCursor(0,2);

lcd.print(LCDline[2]);

lcd.setCursor(0,3);

lcd.print(LCDline[3]);

delay(1000); // 1 second

}

void setup()

{

lcd.init(); // initialize the lcd

lcd.init();

// Print a message to the LCD.

lcd.backlight();

LCDline[0] = " Hello world!";

LCDline[1] = "MIA>>Monitor=MIAtor";

LCDline[2] = "bastelbude.grade.de";

LCDline[3] = " ver. 2017-12-20";

Serial.begin(115200);

CAN0.begin(CAN_500KBPS); // init can bus : baudrate = 500k

pinMode(2, INPUT); // Setting pin 2 for /INT input

Serial.println("MCP2515 Library Receive Example...");

//myPrint();

}

void loop()

{

if(!digitalRead(2)) // If pin 2 is low, read receive buffer

{

CAN0.readMsgBuf(&len, rxBuf); // Read data: len = data length, rxBuf = data byte(s)

rxId = CAN0.getCanId(); // Get message ID

if (rxId == 0x620) // battery related messageID 620

{

LCDline[0] = "Bat: ";

Volts = ((float)(rxBuf[2]*256+rxBuf[3]))/100; // Voltage with decimals

Amps = ((float)(rxBuf[0]*256+rxBuf[1]))/10; // current drawn or regenerated, allow negative

Celsius = ((float)rxBuf[4],3); // Temperature, allow negative

SOC = ((int)rxBuf[5]); // State Of Charge

LCDline[0] = dtostrf(Volts,4,1,myBuf); //set first line

LCDline[0] += "V | ";

LCDline[0] += dtostrf(Amps,6,1,myBuf); //length of string=6 decimal places=1

LCDline[0] += "A |";

LCDline[0] += dtostrf(Celsius,2,0,myBuf); //length of string=2 decimal places=0

LCDline[0] += "C";

switch (rxBuf[6]&0x07) { //mask lowest 3 bits (48+49+50) = status

case 0:

Status = "Ready | ";

break;

case 1:

Status = "Run | ";

break;

case 2:

Status = "Downgrad | ";

break;

case 3:

Status = "Charge | ";

break;

case 4:

Status = "Error | ";

break;

case 5:

Status = "Init | ";

break;

case 6:

Status = "Stop | ";

break;

}

if ((rxBuf[6]&0x40)== 0) // bit 54 Emergency

{

Emergency = "noEmerg";

} else {

Emergency = "Emergency";

}

if ((rxBuf[6]>>7)== 1) // bit 55 Regeneration

{

Regeneration = "Regen | ";

} else {

Regeneration = "noRegen | ";

}

SOH = ((int)rxBuf[7]); // State Of Helth

LCDline[1] = Status; //set second line

LCDline[1] += Emergency;

LCDline[2] = Regeneration; // set third line

LCDline[2] += "H=";

LCDline[2] += SOH;

LCDline[2] += " C=";

LCDline[2] += SOC;

LCDline[2] += "%";

Serial.println(); // new line

Serial.print("ID 620 raw data: ");

for(int i = 0; i<len; i++) // Print each byte of the data

{

if(rxBuf[i] < 0x10) // If data byte is less than 0x10, add a leading zero

{

Serial.print("0");

}

Serial.print(rxBuf[i], HEX);

Serial.print(" ");

}

Serial.println();

LCDline[3] = ""; // set fourth line

for(int i = 0; i<len; i++) // Print each byte of the data

{

if(rxBuf[i] < 0x10) // If data byte is less than 0x10, add a leading zero

{

LCDline[3] += "0";

}

sprintf(myBuf,"%hhX",rxBuf[i]);

LCDline[3] += myBuf;

}

myPrint(); // lcd-print and serial-print of all four lines

}

if (rxId == 0x621) // BMS error messageID 621

{

Serial.print("ID 621 raw data: ");

for(int i = 0; i<len; i++) // Print each byte of the data

{

if(rxBuf[i] < 0x10) // If data byte is less than 0x10, add a leading zero

{

Serial.print("0");

}

Serial.print(rxBuf[i], HEX);

Serial.print(" ");

}

Serial.println();

}

if (rxId == 0x622) // BMS > Charger messageID 622

{

ChargeCurrent = ((float)(rxBuf[0]*256+rxBuf[1]))/10; // Amps with decimals

ChargeVoltage = ((float)(rxBuf[3]*256+rxBuf[4]))/100; // Voltage with decimals

Serial.print("ID 622 raw data: ");

for(int i = 0; i<len; i++) // Print each byte of the data

{

if(rxBuf[i] < 0x10) // If data byte is less than 0x10, add a leading zero

{

Serial.print("0");

}

Serial.print(rxBuf[i], HEX);

Serial.print(" ");

}

Serial.println();

}

}

}

DC charging

CCS

- prerequisites

- explore V2G protocol

- discover BMS <> Charger CANbus conversation

- develop BMS <> PCL communication

- parts

- CCS-socket e.g. Phoenix Contact ~EUR 800,-

- input voltage monitor

- power contactor (+125A disconnecting device) Tyco ~EUR 150,-

- current monitor

- V2G in-vehicle-charge-controller e.g. EVAcharge SE ~EUR 750,-

- ARM microcontroller

- Linux OS

- fully programmable

- PWM duty cycle detection (CP low level communication)

- switchable resistors (CP low level communication)

- HomePlug Green PHY integration (PLC high level communication)

- Proximity pilot signal input (PP)

- lock-motor output

- lock-motor end switch input

- lock-motor fault pin

- CAN transceiver (BMS communication)

- 6 GPIOs (current-monitoring?, voltage-monitoring?, temprature-monitoring?, power contactor-driver?, (contactor-monitoring?))

(8MHz EUR 4,79)

(8MHz EUR 4,79) (8MHz EUR 4,79)

(8MHz EUR 4,79)